TS SERIES

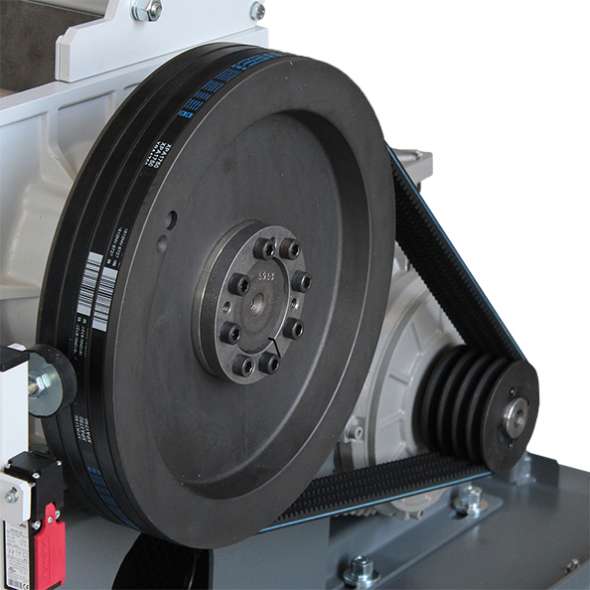

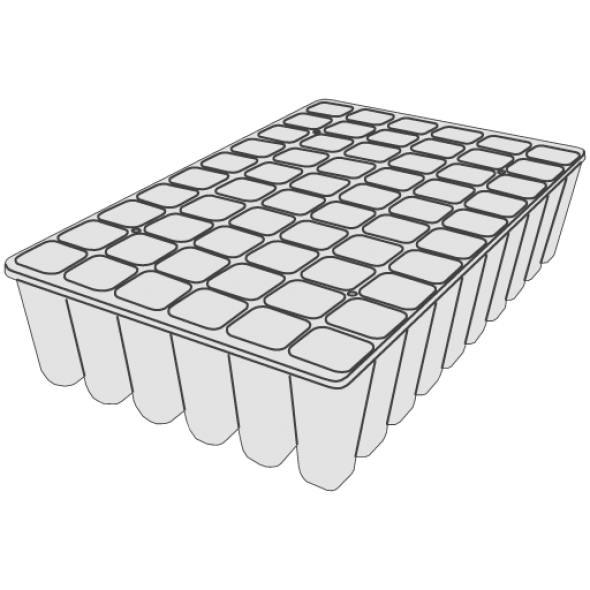

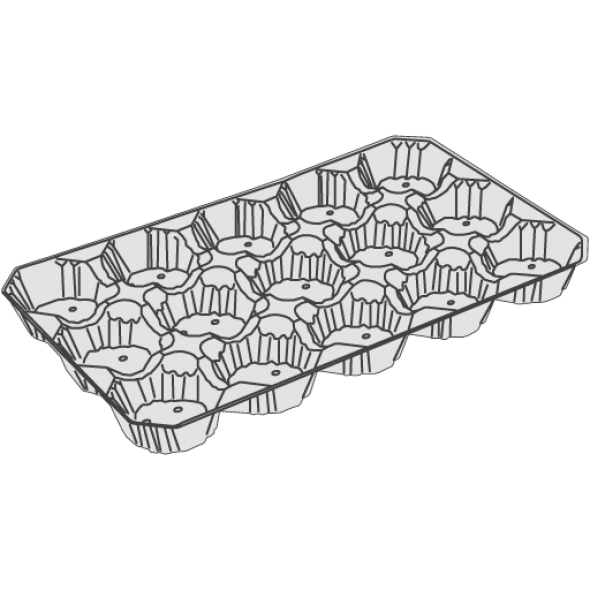

Series of granulators designed for inline recovery of full sheet at start-up, thermoformed and perforated sheet of PP, PS, PET, PLA and Coex ones. Grinding of sheet with cups up to 120 mm height, facing up or down; grinding of thermoformed and warm sheet, thanks to the water cooling system of the grinding chamber. Traction units with adjustable speed and anti-slip knurled rollers, ensure the granulators to work in perfect synchrony with the thermoformer. The new integral soundproof box placed on the ground allows a considerable reduction of the sound level.