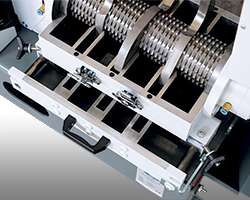

JN SERIES

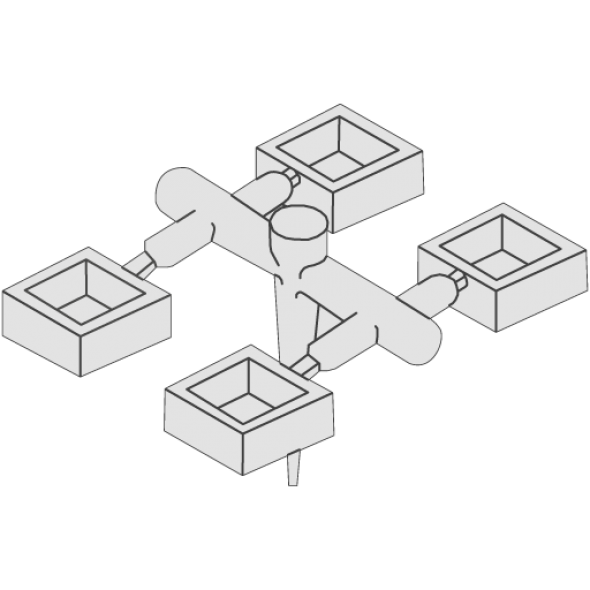

Small footprint, increased grinding chamber inlet, stability in handling and ease of maintenance, these are just some of the improvements adopted in the JN 15 Series. For injection moulding machines, these granulators are ideal for the recovery of sprues and scrap pieces even bulky ones.